-

simulation of cement grinding circuits by bmcs

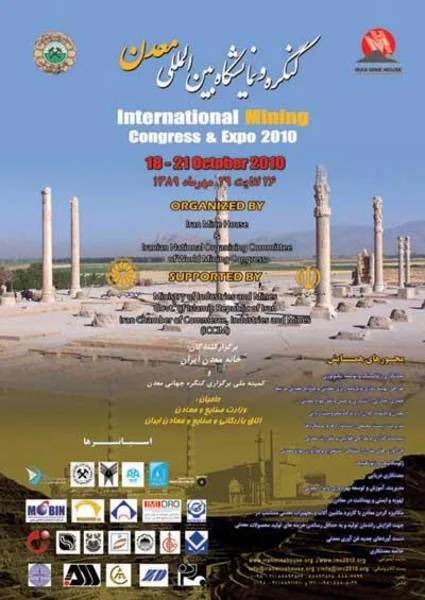

جزئیات بیشتر مقاله- تاریخ ارائه: 1389/07/20

- تاریخ انتشار در تی پی بین: 1389/07/20

- تعداد بازدید: 718

- تعداد پرسش و پاسخ ها: 0

- شماره تماس دبیرخانه رویداد: -

more than 60% of electric energy consumption of cement factories is used to grind raw materials and clinker. due to such a high level of energy consumption, implementation of optimization studies is reasonable. most of installed cement grinding circuits are composed by a multicompartment tube mill in an open circuit or a closed circuit with an air separator. in the present article, simulation of these cement grinding circuits is discussed using bmcs; the ball milling circuits simulator. bmcs software is able to simulate ball mills, hydrocyclones, efficiency curve, stream splitting and junction points, and convergence of closed circuits. in this article, bmcs’s ball mill module is used for simulating compartments of a tube mill, and the efficiency curve module (ecs) is used to simulate an air separator and the diaphragm between the two compartments. bmcs takes advantage of population balance method and weller’s rtd modeling for simulation of ball mills, and whitten’s relationship to simulate efficiency curve.

مقالات جدیدترین رویدادها

-

استفاده از تحلیل اهمیت-عملکرد در ارائه الگوی مدیریت خلاقیت سازمانی و ارائه راهکار جهت بهبود

-

بررسی تاثیر ارزش وجوه نقد مازاد بر ساختار سرمایه شرکت های پذیرفته شده در بورس اوراق بهادار تهران

-

بررسی تأثیر سطح افشای ریسک بر قرارداد بدهی شرکت های پذیرفته شده در بورس اوراق بهادار تهران

-

بررسی تأثیر رتبه بندی اعتباری مبتنی بر مدل امتیاز بازار نوظهور بر نقد شوندگی سهام با تأکید بر خصوصی سازی شرکت ها

-

تأثیر آمیخته بازاریابی پوشاک ایرانی بر تصویر ذهنی مشتری پوشاک ایرانی (هاکوپیان)

-

تحلیل و بررسی شیوه ی اطلاع رسانی نوین در توریسم و گردشگری ایران

-

ارتقا سطح ایمن یترافیک و حمل و نقل از طریق فرهنگ سازی و آموزش رفتارهای ترافیکی به کاربران راهها

-

ژئوشیمی عناصر پلانیتیوم و پالادیوم در پیروکسنیت ها و کرومیت های منطقه فاریاب

-

رابطه سبک های رهبری روسا و مدیران بیمارستان ها با شاخص دهای عملکرد بیمارستان

-

مروری بر راه های موثر در تعیین پاداش هیات مدیره

مقالات جدیدترین ژورنال ها

-

مدیریت و بررسی افسردگی دانش آموزان دختر مقطع متوسطه دوم در دروان کرونا در شهرستان دزفول

-

مدیریت و بررسی خرد سیاسی در اندیشه ی فردوسی در ادب ایران

-

واکاوی و مدیریت توصیفی قلمدان(جاکلیدی)ضریح در موزه آستان قدس رضوی

-

بررسی تاثیر خلاقیت، دانش و انگیزه کارکنان بر پیشنهادات نوآورانه کارکنان ( مورد مطالعه: هتل های 3 و 4 ستاره استان کرمان)

-

بررسی تاثیر کیفیت سیستم های اطلاعاتی بر تصمیم گیری موفق در شرکتهای تولیدی استان اصفهان (مورد مطالعه: مدیران شرکتهای تولیدی استان اصفهان)

-

دین، معنویت و مقابله با سرطان پستان: یک مطالعه ی پدیدارشناسی

-

بررسی تحقق حق الزحمه غیر عادی حسابرسان، چرخش حسابرسان و کیفیت حسابرسی شرکت های پذیرفته شده در بورس اوراق بهادار تهران

-

بررسی شیوع سندرم متقاطع فوقانی در کودکان کم توان ذهنی

-

واکاوی پیامدهای مدگرایی منفی از منظر گزاره های دینی

-

bond between steel reinforcement bars and seawater concrete

سوال خود را در مورد این مقاله مطرح نمایید :