-

optimization of sulfur recovery unit recovery

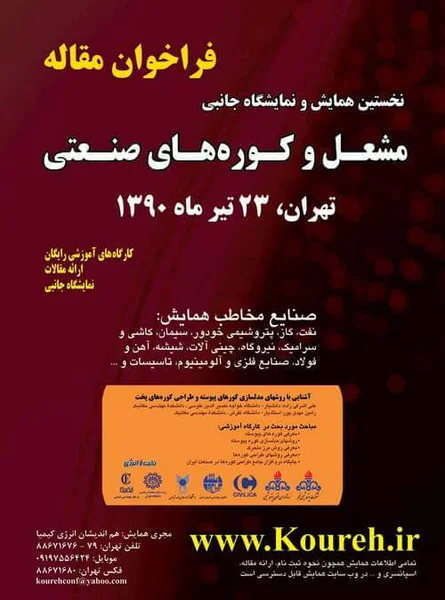

جزئیات بیشتر مقاله- تاریخ ارائه: 1390/04/01

- تاریخ انتشار در تی پی بین: 1390/04/01

- تعداد بازدید: 506

- تعداد پرسش و پاسخ ها: 0

- شماره تماس دبیرخانه رویداد: -

in this sulfur recovery unit (sru), hydrogen sulfide (h2s) is converted to elemental sulfur using modified sulfur recovery unit. in the present study, first the simulation of claus process has been considered using a process simulator called tsweet then the effect of h2s concentration, h2s/co2 ratio and acid gas flow of ag splitter in three different concentrations of oxygen (in input air into the unit) on the main burner temperature and sulfur recovery have been studied and compared. it is shown that temperature of the main burner increases up to maximum temperature increasing fraction of ag splitter flow to main burner then it is reduced by a sharp slope; this is true for all three concentrations of oxygen. however, if two other parameters (concentration of h2s and h2s/co2 ratio) increase, temperature of main burner increases monotonically; this increase has different slopes depending on oxygen concentration in input air. also in this paper it is shown that recovery rate of sulfur increases up to a maximum value then decreases as h2s concentration and h2s/co2 ratio (in all three concentrations of oxygen) increase. if 70-85% acid gas feed are entered the main burner, more optimal sulfur recovery rate than other flows would be achieved.

مقالات جدیدترین رویدادها

-

استفاده از تحلیل اهمیت-عملکرد در ارائه الگوی مدیریت خلاقیت سازمانی و ارائه راهکار جهت بهبود

-

بررسی تاثیر ارزش وجوه نقد مازاد بر ساختار سرمایه شرکت های پذیرفته شده در بورس اوراق بهادار تهران

-

بررسی تأثیر سطح افشای ریسک بر قرارداد بدهی شرکت های پذیرفته شده در بورس اوراق بهادار تهران

-

بررسی تأثیر رتبه بندی اعتباری مبتنی بر مدل امتیاز بازار نوظهور بر نقد شوندگی سهام با تأکید بر خصوصی سازی شرکت ها

-

تأثیر آمیخته بازاریابی پوشاک ایرانی بر تصویر ذهنی مشتری پوشاک ایرانی (هاکوپیان)

-

بررسی آزمایشگاهی رفتار گسیختگی خاکهای سیمانی شده مصنوعی

-

همبستگی عزت نفس و پیشرفت تحصیلی در دانشجویان توانبخشی دانشگاه علوم بهزیستی و توان بخشی تهران

-

بررسی اپیدمیولوژیک آپاندیسیت خوشه ای در استان چهارمحال و بختیاری

-

تأثیر خوراکی عصاره گزنه بر بیان عامل رشد دگرگون کننده-بتا (tgf-β) در میزبان های واجد تومور

-

بررسی رفتار پی های رادیه- ریزشمع در خاک رس کرمان (مطالعه موردی: برج جمهوری)

مقالات جدیدترین ژورنال ها

-

مدیریت و بررسی افسردگی دانش آموزان دختر مقطع متوسطه دوم در دروان کرونا در شهرستان دزفول

-

مدیریت و بررسی خرد سیاسی در اندیشه ی فردوسی در ادب ایران

-

واکاوی و مدیریت توصیفی قلمدان(جاکلیدی)ضریح در موزه آستان قدس رضوی

-

بررسی تاثیر خلاقیت، دانش و انگیزه کارکنان بر پیشنهادات نوآورانه کارکنان ( مورد مطالعه: هتل های 3 و 4 ستاره استان کرمان)

-

بررسی تاثیر کیفیت سیستم های اطلاعاتی بر تصمیم گیری موفق در شرکتهای تولیدی استان اصفهان (مورد مطالعه: مدیران شرکتهای تولیدی استان اصفهان)

-

بررسی رابطه باورهای فراشناختی با سلامت دانش آموزان دختر مقطع متوسطه

-

رابطه جدایی مالکیت از کنترل با محافظه کاری غیرشرطی حسابداری شرکت ها

-

تاثیر حاکمیت شرکتی بر ثبات مالی و دسترسی به خدمات مالی در بانک های پذیرفته شده در بورس اوراق بهادار تهران

-

بررسی رابطه بین ساختار مالکیت، ترکیب اعضای هیئت مدیره و سرعت گزارشگری مالی در شرکت های پذیرفته شده در بورس اوراق بهادار تهران

-

بررسی عملکرد انتشار اوراق مشارکت شهرداری مشهد بر اساس مدل swot -ahp

سوال خود را در مورد این مقاله مطرح نمایید :